John Galligan, President of Newburyport, Mass.-based Bradford & Bigelow (B&B), describes why the offset and digital book manufacturer acquired a Muller Martini/Kolbus case binding line to complement its existing coil, perfect, and saddle-stitching capabilities. B&B also invested in automated palletizing equipment while attending drupa.

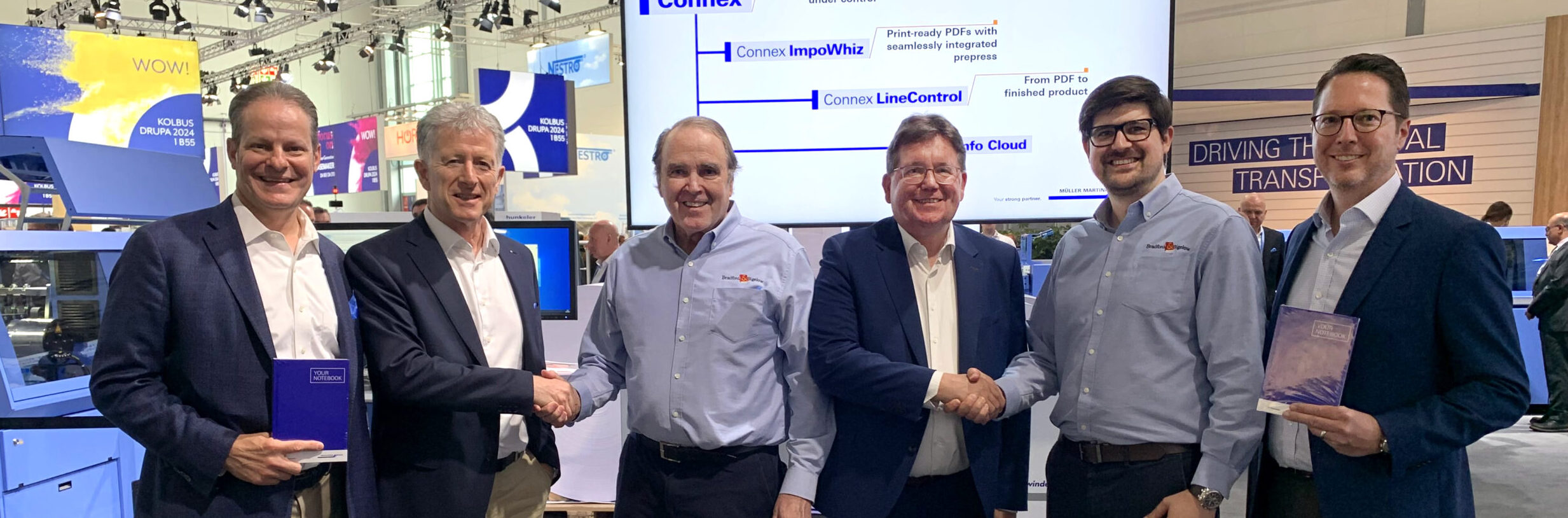

Muller Martini & Kolbus Executives Congratulate B&B on Case Binding Investment

“B&B is pleased to add case binding capacity to meet the needs of clients who are looking for better, much better turn times than what the industry currently offers today” commented John Galligan, CEO.

The enhanced speeds and makeready times of the Muller Martini and Kolbus equipment will make our case binding platform one of the most efficient and cost effective in the industry. “Our goal is to deliver case bound products to our clients in three weeks or less” stated Imanol Cortazar, VP of Process Improvement.

Rick Dunn added “Muller Martini and Kolbus have been long-term, reliable partners for B&B. We are delighted to expand the partner for the benefit of our clients who are looking for more responsive lead times and top-notch quality.”

“With the addition of case binding, B&B will be able to offer 1-4 color offset and digital printing, case, perfect, saddle and coil binding from one plant and one CSR, greatly simplifying the supply chain and turn times for our loyal clients who have made this investment possible” said Karl Shearer, VP Sales & Marketing.